TM 9-2320-365-34-2

21-12. P4 PLANETARY CARRIER ASSEMBLY REPAIR

This task covers:

a. Disassembly

b. Cleaning/Inspection

c. Assembly

d. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Transfer case module disassembled (para 22-3).

Tools and Special Tools

Tool Kit, Genl Mech (Item 68, Appendix B)

Gloves, Rubber (Item 23, Appendix B)

Goggles, Industrial (Item 25, Appendix B)

Wrench, Torque, 0-300 lb-in. (Item 83, Appendix B)

Caliper, Vernier (Item 8, Appendix B)

Adapter, Socket Wrench, (Item 3, Appendix B)

Tools and Special Tools (Cont)

Socket Wrench Attachment, Screwdriver (TM 9-

2320-365-20)

Materials/Parts

Rag, Wiping (Item 59, Appendix C)

Grease, Automotive and Artillery (Item 36,

Appendix C)

Solvent, Dry Cleaning (Item 81, Appendix C)

Setscrew (3) (Item 287, Appendix F)

a. Disassembly.

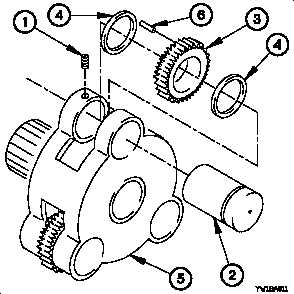

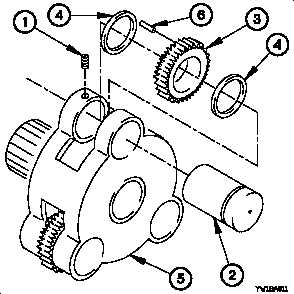

(1) Remove setscrew (1), spindle (2), pinion gear (3), and

two thrust washers (4) from planetary carrier (5).

Discard setscrew.

(2) Remove 18 roller bearings (6) from pinion gear (3).

(3) Perform steps (1) and (2) on remaining two pinion gears.

b. Cleaning/Inspection.

WARNING

Dry Cleaning Solvent (P-D-680) is TOXIC and flammable. Wear protective goggles and

gloves; use only in well ventilated area; avoid contact with skin, eyes, and clothes, and do

not breathe vapors. Keep away from heat or flame. Never smoke when using solvent; the

flashpoint for Type I Dry Cleaning Solvent is 100°F (38°C) and for Type II is 130°F (50°C).

Failure to comply may result in serious injury or death to personnel.

If personnel become dizzy while using cleaning solvent, immediately get fresh air and

medical help. If dry cleaning solvent contacts skin or clothes, flush with cold water. If dry

cleaning solvent contacts eyes, immediately flush eyes with water and get immediate medical

attention. Failure to comply may result in injury to personnel.

(1) Clean all metal parts with dry cleaning solvent.

21-59