TM 9-2320-365-34-2

Section II. MAINTENANCE PROCEDURES

21-2. TRANSMISSION REPAIR

This task covers:

a. Disassembly

b. Inspection

c. Assembly

d. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Transmission mounted on maintenance stand (para

7-5).

Transfer case module removed (para 22-2).

Scavenge pump assembly removed (para 7-16).

Control valve module removed (para 7-10).

Torque converter removed (para 7-2).

Tools and Special Tools

Tool Kit, Genl Mech (Item 68, Appendix B)

Pliers, Retaining Ring (Item 37, Appendix B)

Suitable container [33 qt (31 L) capacity]

Caliper, Vernier (Item 8, Appendix B)

Straight Edge (Item 61, Appendix B)

Caliper Set, Micrometer, Outside (Item 7, Appendix

B)

Indicator, Dial (Item 30, Appendix B)

Tools and Special Tools (Cont)

Caliper, Micrometer, Inside (Item 6, Appendix

B)

Wrench, Torque, 0-175 lb-ft (Item 80, Appendix

B)

Gage, Profile (TM 9-2320-365-20)

Materials/Parts

Gasket (Item 32, Appendix F)

Gasket (Item 37, Appendix F)

Gasket (Item 38, Appendix F)

Lubricating Oil, Engine (Item 44, Appendix C)

Cloth, Abrasive (Item 23, Appendix C)

Personnel Required

(2)

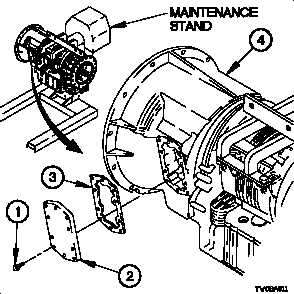

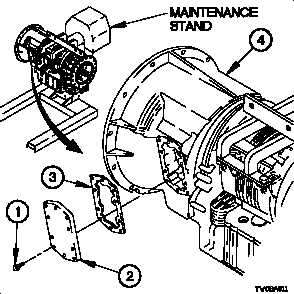

a. Disassembly

NOTE

Perform step (1) if transmission is equipped

with PTO cover.

(1) Remove 10 bolts (1), PTO cover (2) and gasket (3) from

torque converter housing (4). Discard gasket.

21-2