TM 9-2320-365-34-2

20-5. CRANKSHAFT AND MAIN BEARINGS REPLACEMENT/REPAIR (CONT)

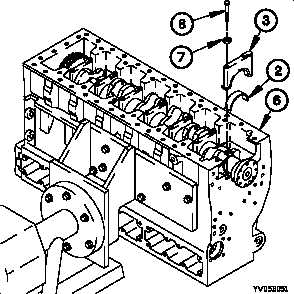

(10) Tighten 14 bolts (8) an additional 1/4 turn.

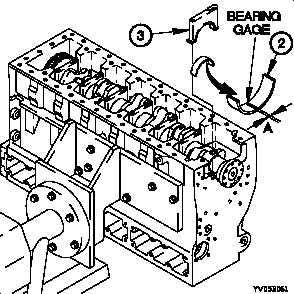

(11) Remove 14 bolts (8), washers (7), seven crankshaft

main bearing caps (3) and main bearings (2) from

cylinder block (6).

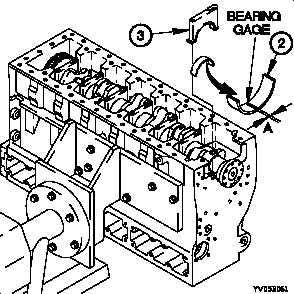

(12) Measure largest width (A) of each bearing gage with

chart contained with gage package. Clearance should

be 0.003-0.006 in. (0.007-0.015 cm).

(13) Discard bearing gage from seven main bearings (2) after

recording clearance.

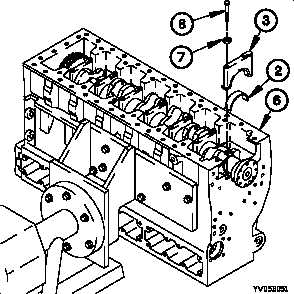

(14) Perform steps (8) through (10) to install seven crankshaft

main bearings caps (3).

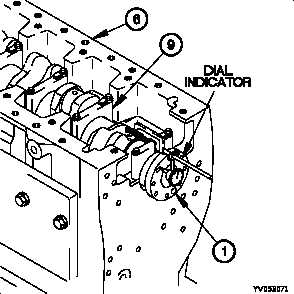

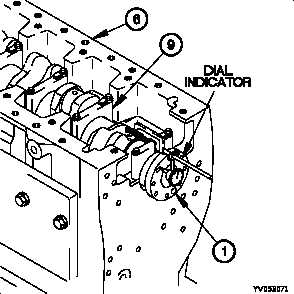

(15) Mount dial indicator on cylinder block (6).

(16) Align dial indicator with crankshaft (1) and adjust

indicator to read zero.

(17) Rotate crankshaft (1) and observe end play reading.

(18) End play must be 0.003-0.009 in. (0.007-0.023 cm). If

end play exceeds tolerance replace thrust bearing in No.

6 main bearing journal (9).

(19) Remove dial indicator from cylinder block (6).

20-34