TM 9-2320-365-34-2

21-15. C7 CLUTCH HOUSING AND FRONT OUTPUT HOUSING ASSEMBLY REPAIR

(CONT)

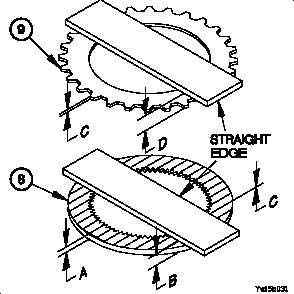

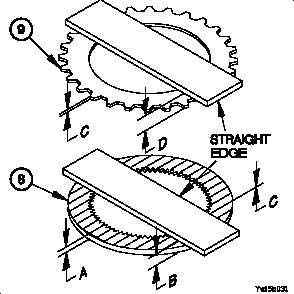

(9) Inspect five C7 friction plates (8) for wear.

(10) Measure thickness (A) of each C7 friction plate (8).

Minimum thickness is 0.087 in. (2.210 mm).

(11) Lay straight edge across each C7 friction plate (8),

subtract measurement (B) from (A), maximum bend

0.010 in. (0.254 mm).

(12) Measure oil groove depth (A) of each C7 friction plate

(8), minimum oil groove depth is 0.008 in. (0.203 mm).

(13) Inspect C7 five reaction plates (9) for wear.

(14) Measure thickness (C) of each C7 reaction plate (9).

Minimum thickness is 0.083 in. (2.108 mm).

(15) Lay straight edge across each C7 reaction plate (9),

subtract measurement (D) from (C), maximum bend is

0.010 in. (0.254 mm).

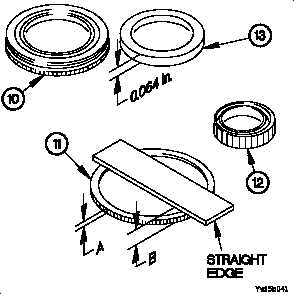

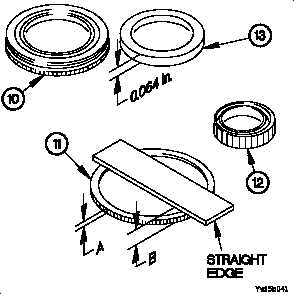

(16) Inspect C7 piston (10) for excessive seal ring groove

wear and burring.

(17) Inspect C7 backing plate (11) for wear.

(18) Measure thickness (A) of each C7 backing plate.

Minimum thickness is 0.34 in. (8.64 mm).

(19) Lay straight edge across each C7 backing plate (11),

subtract measurement (B) from (A), maximum bend is

0.010 in. (0.254 mm).

(20) Inspect C7 clutch hub (12) for scoring and burring.

(21) Inspect shim(s) (13) for cracks and burring. Measure

shims for total thickness of 0.064 in. (1.626 mm). Add

or subtract shims to achieve proper dimension.

21-74