TM 9-2320-365-34-2

7-17. ENGINE AND TRANSMISSION MOUNT BRACKET REPLACEMENT

This task covers:

a. LH Removal

b. LH Installation

c. RH Removal

d. RH Installation

e. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Engine shut down (TM 9-2320-365-10).

M1079 van body removed (TM 9-2320-365-20-4).

Tools and Special Tools

Tool Kit, Genl Mech (Item 68, Appendix B)

Goggles, Industrial (Item 25, Appendix B)

Wrench, Torque, 0-600 lb-ft (Item 85, Appendix B)

Wrench, Torque, 0-175 lb-ft (Item 80, Appendix B)

Wrench Set, Socket (Item 75, Appendix B)

Tools and Special Tools (Cont)

Jack, Dolly Type, Hydraulic (Item 31, Appendix

B)

4x4x8 in. (20 cm) wooden piece

Materials/Parts

Nut, Self-locking (2) (Item 146, Appendix F)

Sealant, Pipe (Item 67.1, Appendix C)

Personnel

(2)

WARNING

Wear appropriate eye protection when

working under vehicle due to the

possibility of falling debris. Failure to

comply may result in injury to

personnel.

a. LH Removal.

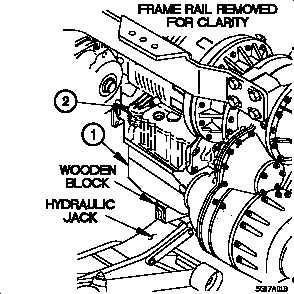

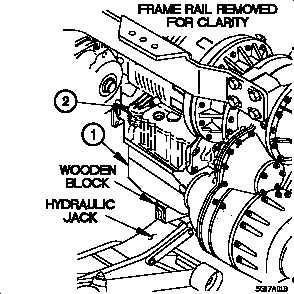

NOTE

Hydraulic jack is used to support engine

and transmission while LH engine and

transmission mount bracket is being

replaced.

(1) Position hydraulic jack with 8 in. (20 cm) wooden block

under transmission control valve module (1).

(2) Raise hydraulic jack to apply pressure to transmission

(2).

Change 1

7-99