TM 9-2320-365-34-2

7-12. MAIN VALVE BODY ASSEMBLY REPAIR

This task covers:

a. Disassembly

b. Cleaning/Inspection

c. Assembly

d. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Control valve module disassembled (para 7-11).

Tools and Special Tools

Tool Kit, Genl Mech (Item 68, Appendix B)

Multimeter, Digital (Item 34, Appendix B)

Caliper, Vernier (Item 8, Appendix B)

Wrench, Torque, 0-60 N·m (Item 84, Appendix B)

Wrench Set, Socket (Item 75, Appendix B)

Press, Arbor, Hand Operated (Item 41, Appendix B)

Spring Compression Tool, Main Valve Body (Item 11,

Appendix D)

Tools and Special Tools (Cont)

Goggles, Industrial (Item 25, Appendix B)

Gloves, Rubber (Item 23, Appendix B)

Materials/Parts

Rag, Wiping (Item 59, Appendix C)

Packing, Preformed (Item 177, Appendix F)

Packing, Preformed (Item 175, Appendix F)

Filter Element (Item 25, Appendix F)

Solvent, Dry Cleaning (Item 81, Appendix C)

Dispenser, Pressure Sensitive Adhesive Tape

(Item 31, Appendix C)

a. Disassembly.

CAUTION

The main valve body contains parts which

cannot be interchanged. Tag all parts prior

to removal. Failure to comply may result in

damage to equipment.

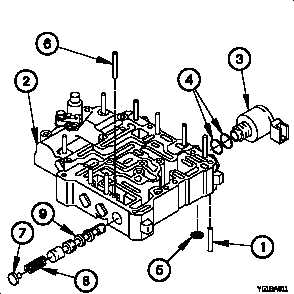

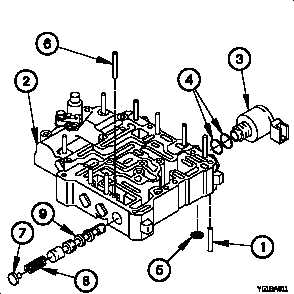

(1) Remove retaining pin (1) from main valve body (2).

(2) Remove solenoid (3) from main valve body (2).

(3) Remove two preformed packings (4) from solenoid (3).

Discard preformed packings.

(4) Remove solenoid filter screen (5) from main valve

body (2). Discard solenoid filter screen.

WARNING

Use care when removing springs.

Springs are under tension and can act

as projectiles when released. Failure to

comply may result in injury to

personnel.

(5) Remove retaining pin (6), stop (7), spring (8), and C2

latch valve (9) from main valve body (2).

7-81