TM 9-2320-365-34-2

Section II. MAINTENANCE PROCEDURES

7-2. TORQUE CONVERTER REPLACEMENT/REPAIR

This task covers:

a. Removal

b. Disassembly

c. Cleaning/Inspection

d. Assembly

e. Installation

f. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Transmission mounted on maintenance stand (para 7-5).

Tools and Special Tools

Tool Kit, Genl Mech (Item 68, Appendix B)

Wrench, Torque, 0-175 lb-ft. (Item 80, Appendix B)

Gage, Profile (TM 9-2320-365-20)

Caliper, Vernier (Item 8, Appendix B)

Caliper Set, Micrometer Inside (Item 6, Appendix B)

Straight Edge (Item 61, Appendix B)

Gage Set, Telescoping (Item 21, Appendix B)

Gage, Depth, Micrometer (Item 22, Appendix B)

Pan, Drain (Item 36, Appendix B)

Inserter, Bearing and Bushing (TM 9-2320-365-20)

Socket Wrench Attachment, Screwdriver (Item 74,

Appendix B)

Goggles, Industrial (Item 25, Appendix B)

Gloves, Rubber (Item 23, Appendix B)

Chain, Welded (TM 9-2320-365-10)

Adapter (3/8 to 1/2") (NSN 5120-01-335-0701)

Tools and Special Tools (Cont)

Socket Wrench Attachment, Screwdriver (3/4

Hex, 1/2 Drive) (NSN 5120-01-367-3468)

Materials/Parts

Packing, Retainer (Item 217, Appendix F)

Washer, Seal (Item 300, Appendix F)

Sealring (Item 281, Appendix F)

Spring, Flat (13) (Item 290, Appendix F)

Packing, Retainer (Item 216, Appendix F)

Bolt, Machine (2) (Item 15, Appendix C)

Washer, Flat (2) (Item 92, Appendix C)

Rag, Wiping (Item 59, Appendix C)

Solvent, Dry Cleaning (Item 81, Appendix C)

Personnel Required

(2)

a. Removal.

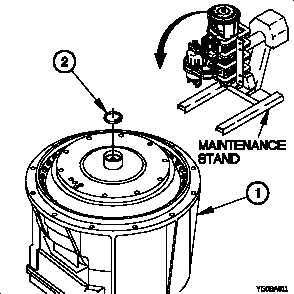

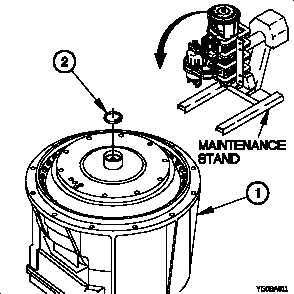

(1) Rotate transmission on maintenance stand so that torque

converter module (1) is in up position.

WARNING

Use care when removing retaining rings.

Retaining rings are under tension and can

act as projectiles when released. Failure

to comply may result in injury to

personnel.

NOTE

Perform steps (2) through (6) on transmission

serial numbers prior to 6510165560.

(2) Remove retaining ring (2) from torque converter module

(1).

7-2

Change 1